Single Phase Electric Motor/Winding Testing

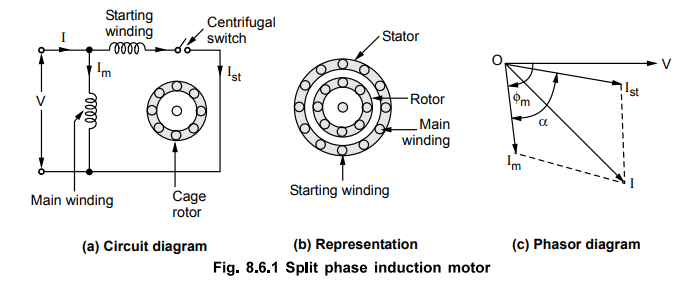

Diagram Of Single Phase Electric Motor.

Aim: To test and identify the main winding(Running Winding) and auxiliary windings((Starting Winding ) of a single-phase motor using a multimeter, and to establish the correct electrical connections for proper motor operation.

Apparatus Required:

- Digital Multimeter

- Connecting Wires

- Tester

- Single phase motor

- Hand gloves

- Note pad to calculate the value

Identifying. Single Phase Electric Motor

Terminals: Single Phase Electric Motor typically have two windings:

- Running (Main) Winding: Provides continuous operation.

- Starting (Auxiliary) Winding: Assists in motor start up.

Testing Procedures :Single Phase Electric Motor

1.Continuity Test (Open Circuit Detection):

Purpose: To verify that the windings are not broken (i.e., no open circuits).

Procedure:

- Set the multimeter to the continuity mode.

- For the Running Winding:

- Connect one terminal and other terminal of the winding.

- A continuous beep indicates the winding is intact; no beep suggests an open circuit.

- For the Starting Winding:

- Connect one terminal and other terminal of the winding.

- Interpret the results as above.

2. Resistance Test:

Purpose: To measure the resistance of each winding and identify discrepancies.

Procedure:

- Set the multimeter to the resistance (ohms) setting.

- Measure the resistance between:

- Running Winding

- Starting Winding

- Compare the readings:

- The starting winding typically has higher resistance than the running winding due to thinner wire and more turns.

- Significantly different readings may indicate issues such as shorted turns or partial opens.

- 3. Insulation Resistance Test:

Purpose: To ensure there is no short circuit between the windings and the motor frame.

Procedure:

- Set the multimeter to the highest resistance range.

- Connect one probe to the motor frame (ground).

- For each winding terminal, connect the other probe and measure the resistance.

- A very high resistance indicates good insulation; low resistance suggests a short to the frame.

Now, For Resistance Measurement:

Identify Terminals: Label the terminals as T1, T2, and T3 if not already marked.

Measure Resistances Between :

- T1 and T2

- T1 and T3

- T2 and T3

Terminal Identification:

- The highest resistance indicates the path through both the main and starting windings Called Common windings

- The intermediate resistance corresponds to the starting winding

- The lowest resistance pertains to the main winding/Running Winding

Results/Observation: Single Phase Electric Motor

| Terminal Pair | Resistance (Ω) Value | Winding Identification |

| T2and T3 | 406 | T1(Common=Both Starting & Running Winding) |

| T1 and T2 | 165 | T2(Running Winding) |

| T1 and T3 | 243 | T3 (Starting Winding) |

Connecting to Power Supply:

Power Supply: Connect the live wire to the common Winding terminal.

Running Winding : Connect to the neutral wire.

Starting Winding : Connect in series with a starting capacitor, and then to the neutral wire.

- Capacitor: Connect one end to the Start terminal and the other end to the Run terminal.

- Reversing Motor Direction:

- To reverse the motor’s rotation, interchange the connections of the running and starting windings.

Safety Precautions:

- Ensure the motor is completely disconnected from any power source before performing measurements.

- Use a properly functioning multimeter set to the correct measurement range.

- Double-check all connections and measurements to ensure accuracy.

Conclusion:

By performing these resistance measurements and analyzing the results, you can accurately identify the start, run, and common windings of a motor. This information is crucial for proper wiring and troubleshooting of the motor.